- Commercial Security Gates

Cantilever Slide GatesSuper smooth operation. Browse our selection of cantilever slide gate designs.

Cantilever Slide GatesSuper smooth operation. Browse our selection of cantilever slide gate designs. Pedestrian PortalsProvide reliable entry and exit control to all types of secure and restricted areas.

Pedestrian PortalsProvide reliable entry and exit control to all types of secure and restricted areas. Automated Security Gate SystemsSecurity gates with integrated operators.

Automated Security Gate SystemsSecurity gates with integrated operators. Heavy Duty Swing Gate*Closes single clear openings up to 35 feet wide.

Heavy Duty Swing Gate*Closes single clear openings up to 35 feet wide. Huge GatesFor very large clear openings that require a high level of security.

Huge GatesFor very large clear openings that require a high level of security.  Vertical Lift Gate*Standard design closes single clear openings up to 60 feet wide.

Vertical Lift Gate*Standard design closes single clear openings up to 60 feet wide. Overhead GatesRugged, reliable, low maintenance protection for high cycle applications in extreme climates or limited space.

Overhead GatesRugged, reliable, low maintenance protection for high cycle applications in extreme climates or limited space. Custom Gate DesignsWork directly with our design, specification, and engineering teams to design your own custom solution.

Custom Gate DesignsWork directly with our design, specification, and engineering teams to design your own custom solution. Pedestrian Swing GatesSafeguard points of pedestrian ingress and egress.

Pedestrian Swing GatesSafeguard points of pedestrian ingress and egress. SecurFold Bi-Folding Speed GateIndependently tested and certified to 200,000 cycles.

SecurFold Bi-Folding Speed GateIndependently tested and certified to 200,000 cycles.

- Crash Barriers

- Correctional Systems

- Markets

- Specifications & Drawings

- Fabrication Solutions

- About

- Contact TYMETAL

Waterjet Cutting

Custom Waterjet Cutting in the Northeast U.S.

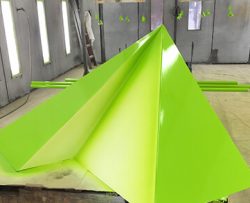

Waterjet cutting enables you to get sleek, precise line cuts in a wide variety of materials and thicknesses. At TYMETAL, we offer 5-axis waterjet cutting services that give your projects the power of precision from custom waterjet cutting.

Advantages of Using Waterjet Cutting Services for Businesses

Waterjet cutting has many advantages that set it apart from other methods, like laser cutting and machine cutting. The versatile properties of waterjet cutters make them suitable for many projects and on almost any material with high precision. Some significant advantages of this service are its:

- Cold cutting process: Since waterjets work without high heat, you can use them on almost any material for clean cuts and little material deformation. There will be no stress on your material, dangerous fumes or warping from extreme temperatures.

- 3-D cutting capabilities: TYMETAL has the latest waterjet cutting head technology. When equipped with this advanced machinery, waterjets can cut 3D shapes allowing for beveled edges and weld prep surfaces.

- Ability to cut thicker material: Our waterjet generates a jet stream that cuts materials measuring from 0.005″ up to 12″ thick. Most production laser cutters will top out at ¾”.

- High accuracy and precision: Our advanced computer programs allow our waterjets to cut through any material with high accuracy and precision. Waterjet systems can make it through tight tolerances that are up to a thousandth of an inch.

- Sustainability: Waterjet cutting leads to virtually no material refuse and eliminates dross waste and slag formation, making waterjet cutting much more environmentally friendly than laser or plasma cutting processes. Both the water from the jet cutting and the abrasive garnet are fully recyclable components.

- Easy programming: Programs for waterjet cutting can handle complicated designs with ease. Programmable computer-aided manufacturing (CAM) software allows operators to import waterjet cutting designs in .dxf and .dwg files, along with 3D models.

- Quick turnaround: Because waterjets use cold cutting at high-speeds, you’ll get a quick turnaround on your projects. Efficiency is one of the most valuable qualities in a manufacturing partner, and our custom waterjet cutting services will help you get things done faster without sacrificing quality.

Waterjet Cutting Capabilities

In the past 15 years, waterjet cutting has become one of the fastest-growing machine tool processes worldwide. The unique capabilities of waterjet cutting make it one of the most versatile production processes, and manufacturers in various industries have found applications for abrasive waterjet technology.

Today, waterjet cutting is a staple in the manufacturing, architectural and agricultural industries. Compared to laser and plasma cutters, waterjet cutting is suitable for a much more comprehensive range of materials.

Choose TYMETAL for Waterjet Cutting Services

At TYMETAL, we offer a full array of complementary metal fabrication services for any product you need us to cut. From traditional laser cutting and plasma cutting to waterjet cutting and large-scale CNC operations, TYMETAL can perform the metal fabrication processes your business needs to make any part or product.

With waterjet cutting, we can cut through virtually every material with minimal waste and a quick turnaround. That ability helps you maintain cost-effective production and shorter lead times.

If you’re looking for waterjet cutting or other metal fabrication within the New York or Northeast U.S. area, TYMETAL has the expertise and state-of-the-art equipment you need. To learn more about custom waterjet cutting, contact us online today. Our team will share more information about what we can do for you.