- Commercial Security Gates

Cantilever Slide GatesSuper smooth operation. Browse our selection of cantilever slide gate designs.

Pedestrian PortalsProvide reliable entry and exit control to all types of secure and restricted areas.

Automated Security Gate SystemsSecurity gates with integrated operators.

Heavy Duty Swing Gate*Closes single clear openings up to 35 feet wide.

Huge GatesFor very large clear openings that require a high level of security.

Vertical Lift Gate*Standard design closes single clear openings up to 60 feet wide.

Overhead GatesRugged, reliable, low maintenance protection for high cycle applications in extreme climates or limited space.

Custom Gate DesignsWork directly with our design, specification, and engineering teams to design your own custom solution.

Pedestrian Swing GatesSafeguard points of pedestrian ingress and egress.

SecurFold Bi-Folding Speed GateIndependently tested and certified to 200,000 cycles.

- Crash Barriers

- Correctional Systems

- Markets

- Specifications & Drawings

- Fabrication Solutions

- About

- Contact TYMETAL

Aluminum versus Steel Gates

When deciding on a gate you need to consider many factors- opening size, security level, whether it should be horizontal slide, swing or vertical lift, ornamental or standard, and even the material of the gate itself- aluminum or steel.

ALUMINUM VS. STEEL SECURITY GATES

While these materials may seem similar, the facts regarding physical properties and internal mechanisms show that the material you select for your security gate may be the most crucial decision of all.

So, what is the difference between an aluminum and a steel gate, and which is the best choice for your application? Here’s what you need to know about these two materials when choosing a gate.

DOUBLE CLEAR OPENINGS UP TO 60′

STEEL GATES RUST, ALUMINUM DOES NOT

Steel is corrosive and aluminum is not. Even galvanized steel can rust in some areas. While all the joints in a steel gate may be welded, each joint is painted with only a cold galvanizing paint that breaks down over time. When the joints are exposed to rain, ice and snow, the breakdown process speeds up, decreasing the gate’s product life. The appearance soon begins to deteriorate and you are left with an eyesore at the customer entrance. Hot dip galvanizing would eliminate the need to apply cold galvanizing paint at welded joints, but the hot dip process does not handle extremely large gates well (limited to tank size) or gates that need to remain perfectly straight and level (the heat for a hot dip process can often introduce slight warping to large complex gate panels). Steel gate panels are often painted, but a moving gate can get chipped or have holes drilled into it for accessories, causing penetrations which open up the steel structure to rust.

Aluminum, however, is protected by a thin layer of its natural corrosion properties, aluminum oxide. The aluminum oxide is a natural, rust-resistant shield. Aluminum oxide acts as a shield because when it comes in contact with water, the aluminum and oxygen molecules can shift apart more than 50% from their normal molecular positions. As a result, when the outer layer of aluminum oxide gets wet, its structure changes just enough to become chemically inert and unable to react rapidly with additional water molecules or atmospheric oxygen. Because of this change in molecular structure, aluminum gates remain aesthetically pleasing for years.

The end result is that, in the competition between steel and aluminum gates, aluminum is the smart choice for long-term durability. The extra investment today gives you a product that will last longer and require less maintenance over the long term.

WHAT ARE ALUMINUM ALLOY GATES?

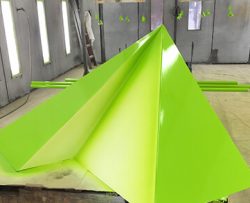

TYMETAL uses naturally protected aluminum, as well as 6063-T6 and 6105-T6 alloys. These alloys were specifically designed for gate frame and track applications to enhance the corrosion resistance, tensile strength, and yield strength of aluminum. The structural integrity of the joints remains intact – and the opening to a facility is protected by a gate that both the installer and owner remain proud of year after year. The lighter weight aluminum offers more strength per lb. and a lighter gate with less effort than heavy steel gates. Less effort equal lower operating costs and increased reliability, both important considerations for security and safety.

While we often think of steel as being one of the strongest materials available, when you compare the strength per lb. of aluminum vs. that of steel, aluminum is the clear choice. As a result, an aluminum gate from TYMETAL can be counted on to provide the highest level of protection possible for your business.

ALUMINUM VS. STEEL GATE ROLLER SAFETY

Our aluminum gates have another advantage over steel gates – their moving parts. Steel pipe frame gates often move over exposed rollers that have grease fittings for periodic lubrication. When more time sensitive issues require immediate attention, gate maintenance programs can be forgotten. Rollers are neglected. Again, when snow, ice and rain multiply the effects of everyday dust and grime, the rollers can bind at the most unexpected and inconvenient time. Gates become difficult to move and operators become overworked. An even bigger concern is the dangerous pinch point created by an exposed roller. These rollers are hazard-prone due to design.

Aluminum gates benefit from an enclosed truck and trolley that provides protection from the elements, dirt, and other debris. The truck assemblies glide on sealed ball bearings that require no maintenance – they will perform as specified regardless of climate conditions. Pinch points are eliminated without the need for roller covers.

ALUMINUM GATES & ALUMINUM GATE DESIGNS

Thanks to our extensive line of aluminum gates, you’ll find the right solution for your exact needs. Take a look at our complete line of aluminum gates, everything from heavy-duty cantilever slide aluminum gates that close openings up to 60’ (120’ when doubled) to vertical lift gates that are ideal in situations with high usage but insufficient space for a gate opening or retraction.

When you need a solution that stands up to the forces of gravity and wind, you need a box frame cantilever slide gate from TYMETAL Aluminum cantilever slide gates can even extend the life of operators. Because the truck track combination and the lighter weight put less strain on the operator, it uses less power to get the gate moving.

If you need to secure an area between two buildings, we feature heavy-duty swing aluminum gates. Ideal for applications in which full movement of a slide gate is not feasible, our swing aluminum gates are the answer when you have the issue of uneven ground that rises or falls sharply away from the outer side of your gatepost.

EXTENSIVE INVENTORY OF ALUMINUM GATES TO FIT YOUR NEED, NO MATTER HOW COMPLICATED

Whatever your unique situation, our experienced engineers, technical staff and fabricators can design and produce custom aluminum gates for your exact needs. We specialize in providing reliable, secure and robust custom aluminum gate designs for unique and unusual requirements.

MATCHED-SYSTEM ALUMINUM GATES MEAN HIGHEST QUALITY

Unlike other manufacturers of aluminum gates, a system designed and produced by TYMETAL is matched, meaning all parts of your gate will be from one source. Save yourself from the time-intensive troubleshooting and headaches of a gate that has its operator from one source and gate from another. TYMETAL aluminum gates, system-matched, provide you with easier installation and better performance because you won’t have to worry about mismatched hardware.

YOUR TYMETAL CORP. GATE COMES WITH COMPLETE SUPPORT

When you choose TYMETAL, you’re not only getting the best performing and highest quality aluminum gates on the market today, but you’re also getting complete support from our experienced team. You’ll enjoy unmatched technical support and field service, complete specifications, custom project specific drawings and more.

CONTACT TYMETAL FOR GATE SPECS & DRAWINGS

When you need to secure perimeters or close openings, you need the reliable, robust aluminum gate designs from TYMETAL For over 25 years now, we are the industry leader because of our extensive line of matched-system aluminum gates, our exceptional team of engineers and fabricators, and the complete support we provide you. With thousands of installations under our belt, we know what it takes to design and manufacture the best solution for your exact needs.

When it comes to closing openings, TYMETAL is the best by far!