- Commercial Security Gates

Cantilever Slide GatesSuper smooth operation. Browse our selection of cantilever slide gate designs.

Pedestrian PortalsProvide reliable entry and exit control to all types of secure and restricted areas.

Automated Security Gate SystemsSecurity gates with integrated operators.

Heavy Duty Swing Gate*Closes single clear openings up to 35 feet wide.

Huge GatesFor very large clear openings that require a high level of security.

Vertical Lift Gate*Standard design closes single clear openings up to 60 feet wide.

Overhead GatesRugged, reliable, low maintenance protection for high cycle applications in extreme climates or limited space.

Custom Gate DesignsWork directly with our design, specification, and engineering teams to design your own custom solution.

Pedestrian Swing GatesSafeguard points of pedestrian ingress and egress.

SecurFold Bi-Folding Speed GateIndependently tested and certified to 200,000 cycles.

- Crash Barriers

- Correctional Systems

- Markets

- Specifications & Drawings

- Fabrication Solutions

- About

- Contact TYMETAL

Heavy Duty Swing Gate

DOWNLOADS

*For larger clear opening widths contact TYMETAL. Clear opening widths for all security gates will vary depending on several factors, including infill options, wind load, and location. Custom distances are available.

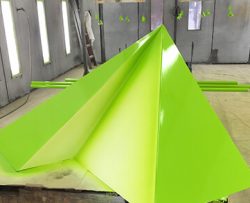

The Fortress Heavy Duty Aluminum Swing Gate, manufactured by TYMETAL, will close openings of up to 35 feet for a single gate and up to 70 feet with the use of a double gate. Contact us today to discuss this barrier in more detail. We also invite you to request drawings and specifications and take advantage of our extensive in-house resources.

Fortress Heavy Duty Swing Gates are fabricated from 6063-T6 aluminum alloy extrusions. The primary members of this commercial swing gate (top and bottom) are rectangular shaped in cross-section with outside vertical members “P” shaped in cross-section. Maintenance-free sealed bearing industrial-grade gate hinges are through-bolted to the gate frame. The gate includes cross bracing of 3/16” minimum diameter stainless steel cable to provide for vertical adjustments.

Security Swing Gate Applications

TYMETAL’s Fortress Heavy Duty Swing gate is ideal for locations where there is not enough room to roll or slide a gate (like alleys or where the access road is right along the perimeter). They are also ideal for the replacement of old steel gates, as they are much lighter and easier to operate both manually or automatically. They will never rust or “brown out” like the steel gates that they are replacing, so they will always look good as an entrance gate.

The Heavy Duty Swing Gate is available in either chain link or ornamental styles to match all popular fencing materials and colors. TYMETAL’s custom design shop can help design a industrial swing gate or other commercial gates to match any element on your site for beautiful security.