- Commercial Security Gates

Cantilever Slide GatesSuper smooth operation. Browse our selection of cantilever slide gate designs.

Cantilever Slide GatesSuper smooth operation. Browse our selection of cantilever slide gate designs. Pedestrian PortalsProvide reliable entry and exit control to all types of secure and restricted areas.

Pedestrian PortalsProvide reliable entry and exit control to all types of secure and restricted areas. Automated Security Gate SystemsSecurity gates with integrated operators.

Automated Security Gate SystemsSecurity gates with integrated operators. Heavy Duty Swing Gate*Closes single clear openings up to 35 feet wide.

Heavy Duty Swing Gate*Closes single clear openings up to 35 feet wide. Huge GatesFor very large clear openings that require a high level of security.

Huge GatesFor very large clear openings that require a high level of security.  Vertical Lift Gate*Standard design closes single clear openings up to 60 feet wide.

Vertical Lift Gate*Standard design closes single clear openings up to 60 feet wide. Overhead GatesRugged, reliable, low maintenance protection for high cycle applications in extreme climates or limited space.

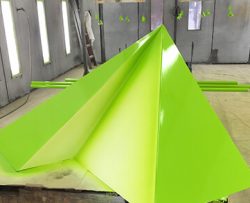

Overhead GatesRugged, reliable, low maintenance protection for high cycle applications in extreme climates or limited space. Custom Gate DesignsWork directly with our design, specification, and engineering teams to design your own custom solution.

Custom Gate DesignsWork directly with our design, specification, and engineering teams to design your own custom solution. Pedestrian Swing GatesSafeguard points of pedestrian ingress and egress.

Pedestrian Swing GatesSafeguard points of pedestrian ingress and egress. SecurFold Bi-Folding Speed GateIndependently tested and certified to 200,000 cycles.

SecurFold Bi-Folding Speed GateIndependently tested and certified to 200,000 cycles.

- Crash Barriers

- Correctional Systems

- Markets

- Specifications & Drawings

- Fabrication Solutions

- About

- Contact TYMETAL

CNC Machining

CNC Machining in the Northeast U.S.

TYMETAL is able to meet your machining needs, as we have both cutting-edge CNC machining and manual machining capabilities. We have a broad spectrum of CNC capabilities, as we can handle large parts on our 30ft FlexDrill and we can also meet tight tolerances on our Haas VF5-40. Our CNC milling has industry-leading capabilities to produce products for countless applications. We have a vast inventory of standard and customized tooling that allows us to machine and mill a wide variety of materials including, but not limited to, aluminum, brass, steel alloys, and even plastic/composites.

Additionally, we are set up to handle your needs from a single custom job to a high volume production run. Our engineering team and skilled operators work together to deliver the consistent quality parts for your specific needs.

CNC Machines

FlexDrill CNC GRD 30-06

Haas VF5-40

Gantry Travel:

- X-Axis: 360”

- Y-Axis: 72”

- Z-Axis: 21”

Features:

- CT40 Spindle Taper

- 4,000 RPM 13.08kW Spindle

- 20 Station Automated Tool Changing

- Dual Rack and Pinion X-Axis Drive

- Ball Screw Y-Axis Drive

- Lead Screw Z-Axis Drive with Nitrogen Assist

- Custom Grid Plate for Repeatable Fixturing

Size Restrictions

No minimum size requirements. Capable of machining parts:

- 48” max length

- 24” max width

- 23” max height

Tolerance

- Holds up two ten-thousandths of an inch tolerance (0.0002 inches)

Drive

- 20 HP Motor for machining the toughest material

- 10,000 RPM limit for the smoothest surface finish

- 2 Speed gearbox for cutting both soft & hardened materials

Tool Capacity

- Holds 20 tools for multiple operations and reduced set-up time

- Holds up to 6” cutters allowing for bulk material removal

Modeling

- World class 3D programming software capable of handling the most challenging machining designs

- Software allows for the development of 3D molds

Additional Features

- Wireless probing for more accurate parts

- Programmable coolant movement to improve surface finish

- Rigid tapping

- Early power failure detection to ensure machine and product safety

- Engraving capabilities

CNC milling allows for a level of consistency and precision that would be difficult—if not impossible—to achieve using manual methods. For more information on our CNC machining capabilities, contact us today!

Advantages of CNC Machining in New York

CNC machines allow you to reach new manufacturing heights using pre-programmed computer software. When you choose CNC machinery for your project, you can improve the following elements of your manufacturing process:

- Increased accuracy: CNC machines have increased accuracy compared to manual alternatives and can produce precise and repeatable results piece after piece for your projects. This boosted accuracy translates to more affordable prices and less waste during the process.

- Increased production speed: With computer maneuvering makes it faster than ever to produce high-quality components and parts. The automated nature of the production speed allows for the production of consistently high-quality work.

- Cost-efficiency: CNC machines require fewer operators, make fewer errors and can create more pieces in less time. These characteristics lead to savings from the beginning of the process and continue to save you money compared to competing milling processes.

CNC Applications

CNC milling is one of the most versatile forms of milling, producing countless projects with precision and consistency. CNC machines work the best on the following projects:

- Aluminum and brass: CNC machines offer effective ways to cut difficult non-ferrous metals. These machines reduce these materials’ increased preparation and attention requirements.

- Prototyping: When you need a flawless model or prototype, consider CNC machinery. We can engineer and reverse-engineer the components you need all within the same software.

Where Do We Serve?

TYMETAL provides solutions to companies across the mid-Atlantic United States. We provide CNC solutions to the following states:

- Vermont

- Rhode Island

- Pennsylvania

- New Jersey

- New Hampshire

- Massachusetts

- Maine

- Delaware

- Connecticut

TYMETAL Metal CNC Machining Services in the Northeast U.S.

TYMETAL has been in business for over 35 years and has practiced and perfected the most cutting-edge metalworking techniques in the industry. To learn more about our CNC machining services, contact us online.