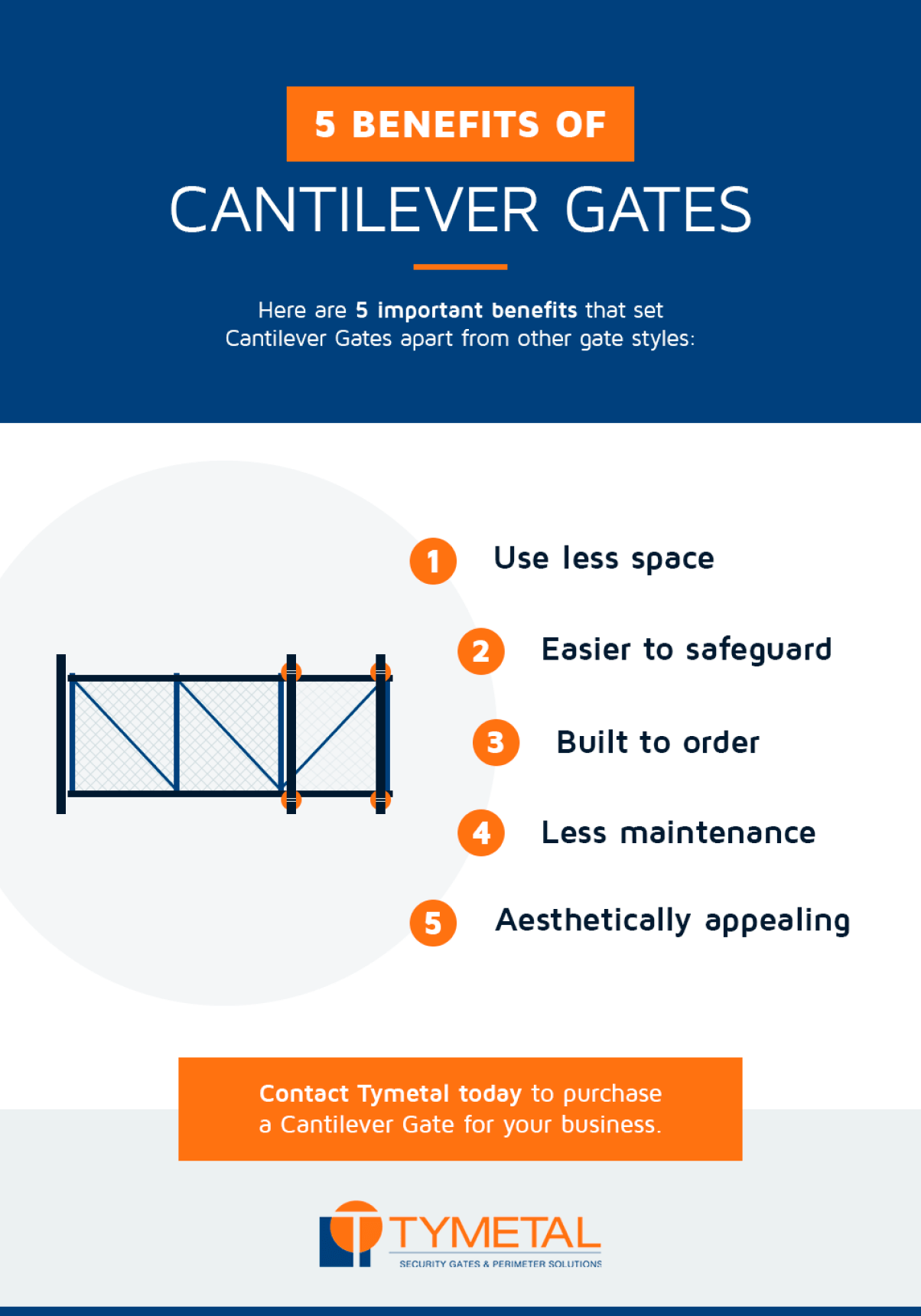

There are several forms of slide gates, to include cantilever, overhead and versions that include a ground track and wheels. The main difference is that Cantilever slide gates are not supported by an overhead track or a ground wheel/track system. Cantilever slide gates are supported by either two or four support posts placed to one side of the gate opening. The cantilever gate panel includes one or two tracks, interlocked and welded to the upper horizontal gate frame member. Truck/trolley assemblies are connected to the support posts and the gate panel with track are slid over the truck assemblies. The gate panel can now easily slide open or closed. Cantilever gates also include a counterbalance portion, which is 50% of the clear opening width. While increasing the length and weight of the gate panel, the counterbalance portion allows the gate to span greater distances. TYMETAL’s use of custom aluminum extrusions and welding techniques enable our cantilever slide gates to span single clear openings up to 60′.

Other forms of slide gates require ground wheels and a ground track or an overhead track. Overhead I beams and ground tracks are costly, particularly that associated with the excavation and installation of a ground track. Grade variations are harder to address, making it more difficult to accommodate normal drainage requirements. .

While cantilever slide gates require more space on one side of the gate opening than other gate styles, if space is available it is often the most efficient and cost effective way to span a vehicular gate opening.