- Commercial Security Gates

Cantilever Slide GatesSuper smooth operation. Browse our selection of cantilever slide gate designs.

Pedestrian PortalsProvide reliable entry and exit control to all types of secure and restricted areas.

Automated Security Gate SystemsSecurity gates with integrated operators.

Heavy Duty Swing Gate*Closes single clear openings up to 35 feet wide.

Huge GatesFor very large clear openings that require a high level of security.

Vertical Lift Gate*Standard design closes single clear openings up to 60 feet wide.

Overhead GatesRugged, reliable, low maintenance protection for high cycle applications in extreme climates or limited space.

Custom Gate DesignsWork directly with our design, specification, and engineering teams to design your own custom solution.

Pedestrian Swing GatesSafeguard points of pedestrian ingress and egress.

SecurFold Bi-Folding Speed GateIndependently tested and certified to 200,000 cycles.

- Crash Barriers

- Correctional Systems

- Markets

- Specifications & Drawings

- Fabrication Solutions

- About

- Contact TYMETAL

Crash Barriers

Crash Gates

- TCGR-12 Cantilever Slide Gate

*Standard design closes single clear openings up to 26 feet wide. - TCG-12 Cantilever Slide Gate (U.S. DOS K12)

*Standard design closes single clear openings up to 18 feet wide. - TCG-4 Cantilevered Slide Gate (U.S. DOS K4)

*Standard design closes single clear openings up to 20 feet wide.

Crash Tested Bollards: Shallow Mount

- Truckstopper 6-30 Removable Or Fixed Bollard

BSI PAS 68 CRASH TESTED as a single bollard (K4 Type) to stop a 16,534 lb. vehicle traveling at 30 mph. - Carstopper 30 Removable Or Fixed Bollard

BSI PAS 68 CRASH TESTED as a single bollard to stop a 3,306 lb. vehicle traveling at 30 mph. - Truckstopper 7-40 Removable Or Fixed Bollard

BSI PAS 68 CRASH TESTED as a single bollard (K8 Type) to stop a 16,534 lb. vehicle traveling at 40 mph. - Truckstopper 3 Fixed Bollard

BSI PAS 68 CRASH TESTED as a single bollard (K4 Type) to stop a 16,534 lb. vehicle traveling at 30 mph with "0" penetration.

- Truckstopper 10-30 Surface Mount Bollard

IWA 14 CRASH TESTED as a single bollard (K4 Type) to stop a 15,873 lb. vehicle traveling at 30 mph. - Truckstopper 5 Removable Or Fixed Bollard

BSI PAS 68 CRASH TESTED as a single bollard (K12 Type) to stop a 16,534 lb. vehicle traveling at 50 mph. - Truckstopper 9 Removable Or Fixed Bollard

IWA 14-1:2013 CRASH TESTED as a single bollard (K12 Type) to stop a 15,873 lb. vehicle traveling at 50 mph. - Universal Slimline Planter 40

Anti-Ram Solution With Style

TYMETAL's Guide to Crash Barriers & Crash Test Ratings

The world is becoming an increasingly dangerous place. The constant threat of terrorist attacks and other forms of violence is very real. It seems that hardly a week goes by without news of another deadly event occurring somewhere in the world. Now more than ever, commercial, industrial and military facilities as well as other large installations must implement strict security measures to safeguard their properties and protect the people and assets housed within them.

A preferred tactic intruders implement is to use some form of heavy vehicle to crash through whatever gate or other security structure has been installed to impede access to a property. Facilities that do not have an effective crash barrier in place may be unable to prevent a potentially catastrophic attack. A crash barrier is a security gate or similar structure specifically designed and constructed to prevent vehicles from penetrating the perimeter of a facility.

Applications/Uses of Crash Barriers

Crash barriers have a number of applications in today’s security-conscious environments. Generally, any property or premises where the need exists to control vehicle (and in some cases, pedestrian) access can benefit from installation of a crash gate or similar barrier:

- Airports: Crash barriers can provide security in public areas such as parking lots, terminals and restricted areas such as hangars and runways.

- Seaports: Crash barriers can provide perimeter security at seaports to minimize the risk of unauthorized entry of persons, materials, or substances.

- Factories: A crash barrier will protect the vulnerable perimeter of virtually any type of industrial factory, manufacturing plant or distribution facility.

- Military bases: Security gates and bollards are ubiquitous sights at military installations for preventing trespassing and forced intrusion via vehicle impact, as well as for controlling the heavy volume of vehicle traffic.

- Border crossings: Crash barriers are vital components for controlling the flow of vehicles across state and national borders, preventing terrorists and other criminals from breaching our borders.

- Public utilities: Strategically placed crash barriers at water treatment plants, power stations and other public utilities can minimize the risk of disruption to these critically important entities.

- Transportation terminals: Crash barriers can help to prevent mass-casualty incidents at busy transportation hubs such as bus and railroad stations by helping to control passenger flow and preventing unauthorized access to vehicles.

Types of Crash Barriers

There are several different types of crash barriers that are commonly used in commercial and industrial applications today:

Crash gates and beams

A crash gate or beam is a barrier that opens and closes manually or automatically to permit entry and exit at high-security facilities such as airports, correctional facilities and military installations. Examples of the various types of crash barriers include:

- Crash tested: This type of gate or beam system has actually been crash tested at an independent testing facility. Depending on when tested, the device has a Department of Defense (DOD), Department of State (DOS) or an ASTM 2656-07 “M” rating. The rating designations most commonly used are K4 (or M30), K8 (or M40) and K12 (or M50). DOD and ASTM 2656-07 ratings will also include a “P” designation to describe the amount of penetration upon impact.

- Engineered: Crash gates and beams can also be “engineered” to perform at the above “crash tested” performance levels. While this classification is not tested, a stamped/certified drawing and statement could be provided by the manufacturer describing the expected performance level.

- Reinforced: This classification applies to a system that could include a steel crash beam, engineered roping or cabling. Although the gate or beam is not tested or engineered to perform at a specific level, it does offer a level of crash resistance beyond that of standard commercial barrier products.

Crash gate systems:

- Cantilever slide gate: Cantilever style gates are a good alternative, assuming sufficient space on one side of the opening to slide (horizontally) the gate open. No ground tracks or overhead supports are necessary. Cantilever gates are supported by two or four posts installed on one side of the roadway/opening and can be automated/operated or not.

- Vertical lift gate: The vertical lift gate is raised to permit entry or exit, making it a more suitable option where there is not sufficient space for a slide gate to open. Vertical lift gates are typically automated/operated.

- Overhead slide gate: The overhead slide gate is supported by an overhead beam and track system. It also slides to one side of the opening to open. Although the overhead beam and track create an overhead restriction, the system is designed to allow tractor trailer and bus type vehicles to pass through. If space/width is a concern, overhead slide gates require less overall space for a given clear opening than cantilever systems. They can be automated/operated or not.

- Swing gate: The swing gate is supported by a post and hinges. They are most appropriate for gate openings having limited activity that do not require automation. While it is possible to automate a swing gate, those that are crash rated can only swing toward the unsecured/public side to open. Because the gate swings out (toward entering traffic) entering vehicles are set back a considerable distance from the gate to allow for its swing path. Given the setback distance and time required for the swing gate to complete its open cycle, security is compromised.

Crash beam systems

- Rotate 90 degrees upward to open. They can be automated/operated or not. Manually operated systems include counter weights to enable a single person to easily open or close the device. Unlike a crash gate beams are intended to provide security against approaching vehicles only, not pedestrians. They are typically available in K4 (M30), K8 (M40) and K12 (M50) versions.

- Should only be considered for use in high security applications such as military, airports, seaports, utilities, embassies, etc.M

- Are not well suited for very active applications and not intended for use as a traffic control device.

- Require the owner to assume responsibility for safe operation, including the provision for all necessary safety features at each barrier location.

Crash bollards

Crash bollards can be posts arranged in a line at predetermined intervals to prevent unauthorized vehicles from accessing a property. Bollards are normally classified as attack- and non-attack resistant. The former is used at facilities such as government and military installations that are vulnerable to a terrorist attack. Innovations in bollard design have led to the development of shallow mount crash-rated bollards featuring Safetyflex technology that are able to withstand extremely high impacts with a shallow foundation. The spring action enables the bollard to bend and absorb the energy, and then return to its original start position after impact.

Understanding Crash Gate Rating Systems

The fact that U.S. government and military installations in our homeland as well as abroad were such glaring targets for a terrorist attack, particularly in the form of a vehicle that rams a security gate, led to the development of a crash barrier rating system. The purpose of the system was to develop and enforce testing standards to verify and certify that the “stopping power” of crash gates achieved certain minimum requirements.

In April, 1985 the U.S. Department of State unveiled (DOS) SD-STD-02.01, which was updated with the Vehicle Crash Testing of Perimeter Barriers and Gates, Revision A in 2003. This standard uses what is referred to as a “K” rating to measure the stopping power of a barrier in relation to the speed and weight of a vehicle that crashes into it. The standard K rating weight for a vehicle was established at 15,000 lbs. In order to meet the standard and achieve certification, the barrier must not permit the penetration of the vehicle’s cargo bed to exceed a distance of more than 3.3 feet (1 meter) beyond the pre-impact inside edge of the barrier.

There are three separate K rating classifications based on the speed of the vehicle upon impact:

- K4 – 30 mph

- K8 – 40 mph

- K12 – 50 mph

As mentioned, the original DoS standard was updated in 2003 for use by the Department of Defense, the Department of Energy and other agencies of the federal government. The upgrade was deemed necessary due to the fact that many State Department installations established in foreign countries included buildings in close proximity with the street and/or other structures, requiring more stringent security measures. The old standard included “distance of penetration” levels L3 (3 ft. or less), L2 (3 ft. to 20 ft.) and L1 (20 ft. to 50 ft.). The new standard eliminated levels L1 and L2, and established an allowable penetration of no more than 1 meter (3.3 ft.).

The State Department no longer certifies crash tests, however, The American Society for Testing and Materials (ASTM) ratings are now the standard for crash test ratings and are used to measure both speed and penetration. Under ASTM International Designation F 2656-07, the speed ratings are differentiated based on the type of vehicle, such as a passenger vehicle, pickup truck, light-duty vehicle, etc.:

- Small passenger car (C) (2430lbs)

- C40 (40mph) (38.0-46.9 mph)

- C50 (50mph) (47.0-56.9 mph)

- C60 (60mph) (57.0mph-above)

- Pickup truck (P)2300 (5070lbs)

- PU40 (40 mph) (38.0-46.9 mph)

- PU50 (50 mph) (47.0-56.9 mph)

- PU60 (60 mph) (57.0-above mph)

- Medium-duty truck (M) (15 000lbs)

- M3050 (30 mph) (28.0-37.9 mph)

- M4065 (40 mph) (38.0-46.9 mph)

- M5080 (50 mph) (47.0-above mph)

- Heavy goods vehicle (H) (65 000lbs)

- H30 (30 mph) (28.0-37.9 mph)

- H40 (40 mph) (38.0-46.9 mph)

- H50 (50 mph) (47.0-above mph)

A “P” rating is assigned to indicate the distance of penetration of the test vehicle upon impact with the barrier. The four classification levels are as follows:

- P1: < 1 m (3.3 ft.)

- P2: 1.01 to 7 m (3.31 to 23.0 ft.)

- P3: 7.01 to 30 m (23.1 to 98.4 ft.)

- P4: 30 m (98 ft.) or greater

- The minimum standoff distance (the distance at which unscreened vehicles and pedestrians are permitted to approach the facility) vs. the allowable property lines

- Maximum allowable vehicle size and speed in relation to current traffic flow

- Current site conditions vs. your requirements in terms of crash barrier foundation

- Security protection level vs. authorized personnel and vehicle accessibility

- Aesthetic appeal of the barrier, which is an especially important consideration in urban environments

As an example, a PU40 P1 crash barrier could stop a pickup truck traveling at 40 mph with a penetration distance no greater than 3.3 ft. An H50 P3 crash barrier would be capable of stopping a heavy goods vehicle moving at greater than 47 mph with a penetration distance between 23.1 and 98.4 ft.

How to Choose a Crash Barrier

Choosing the most appropriate crash barrier for your facility can be a difficult process. Careful consideration of a number of factors is necessary to arrive at the best decision for your organization:

Conduct a comprehensive risk assessment. Before exploring the various crash barrier options, you should take the time to assess the vulnerability of your facility to a vehicle attack. Begin by conducting a thorough investigation to determine high-vulnerability areas. You should also conduct traffic analyses around your facility. These should include traffic and motion studies to assess factors such as the most likely types of attack vehicles and potential paths vehicles may take upon approach. Additionally, clarify your organization’s requirements in terms of securing access points for authorized vehicles. Finally, determine the level or levels of crash protection required (example: M30, M40 and M50).

Select the most appropriate physical perimeter barrier. Once you have completed the risk assessment, you should have a better understanding of the type of crash barrier that will work best at your facility. At this point it is important to evaluate several factors, including:

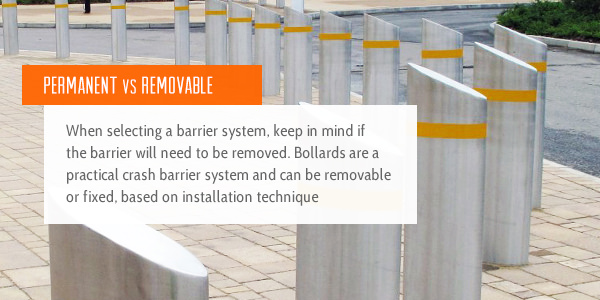

Permanent vs. removable. When selecting a crash barrier, consider if the barrier needs to be permanent or removable. If removable, bollards are typically the most practical crash barrier alternative. Safetyflex offers a technology where the same shallow mount bollard system is capable of functioning as removable or fixed, depending on the installation technique. Due to the larger footings and general structure associated with gate systems and beams they do not have the potential of being portable.

Size of opening. The size of the opening and available space to each side of it will help determine the type of crash barrier you choose. Assuming the need for an automated gate system and sufficient overall space is available, a cantilever slide gate is typically the best option. If there is not sufficient space consider an overhead slide or vertical lift gate. In some situations a slide gate having a ground track may also be an alternative due to its shorter tail length. For security reasons, as a general rule, the barrier opening should be no larger than required.

What crash rating is needed for your facility? Your risk assessment should have given you a strong indication of the types of vehicles that pose the biggest threat to your facility. This will help you determine the best crash barrier for your needs. Use the test ratings to match the barrier to factors such as vehicle type, speed and level of penetration upon impact. Reputable crash barrier manufactures offer products that clearly indicate which (if any) of the DoS/ASTM testing standards that may apply. As a general rule, the higher the rating, the more expensive the product will be, as it requires additional materials to ensure compliance with the higher standard.

Contact TYMETAL to Learn More About Crash Barriers

TYMETAL is a leading designer and manufacturer of high-quality crash barriers for military, defense and other industrial and commercial applications. We offer a wide selection of crash gates, bollards and beams that comply with today’s crash barrier rating standards. We also have the expertise to help you choose the right crash tested perimeter barrier for your needs and budget. Our more than 25 years of experience combined with a capable staff that provides exceptional customer service ensures you get a reliable, cost-effective solution that will protect your facility against your most likely security/terrorism threats.

Contact us for more information regarding crash ratings and other factors that may affect your crash barrier selection process. We will also be able to discuss your specific perimeter security requirements, including any customization needs. If you need to secure your perimeter, you need TYMETAL!